pdf c3 1982 corvette wiring diagram

The 1982 Corvette wiring diagram is essential for restoring and repairing electrical systems‚ showcasing color-coded wires‚ key components‚ and a detailed guide on how to interpret it accurately․

1․1 Overview of the C3 Corvette (1968-1982)

The C3 Corvette‚ produced from 1968 to 1982‚ represents a significant evolution in styling and performance․ Known for its distinctive curved design‚ this generation introduced advancements in both aesthetics and engineering․ The 1982 model marked the final year of the C3 series‚ featuring refinements in electrical systems that laid the groundwork for modern wiring configurations․ Understanding the electrical layout is crucial for restoration and maintenance‚ making the wiring diagram an indispensable resource for owners and enthusiasts of this iconic vehicle․

1․2 Importance of Wiring Diagrams for Restoration and Repair

Wiring diagrams are indispensable for accurately understanding and working on the electrical systems of the 1982 Corvette․ They provide a clear visual representation of wire colors‚ connections‚ and component locations‚ making troubleshooting and repairs more efficient․ These diagrams ensure that restorations maintain original specifications‚ reducing the risk of electrical failures․ For enthusiasts and mechanics alike‚ they serve as a critical guide‚ helping to identify and resolve issues quickly while ensuring safety and preserving the vehicle’s integrity․

Sources for the 1982 Corvette Wiring Diagram

Official GM diagrams‚ online forums like nrjvette․com‚ and specialized Corvette parts suppliers provide accurate and detailed wiring diagrams for the 1982 model․

2․1 Official GM Wiring Diagrams

Official GM wiring diagrams for the 1982 Corvette are highly detailed and accurate‚ offering a comprehensive guide to electrical systems․ These diagrams are sourced directly from GM service manuals‚ ensuring reliability․ They cover the entire wiring harness‚ including color-coded wires‚ connectors‚ and components․ Available as printable PDFs‚ these diagrams are essential for restoration and repair‚ providing a clear layout that helps identify circuits and troubleshoot issues․ Many owners and enthusiasts rely on these diagrams for authenticity and precision in maintaining their classic C3 Corvettes․

2․2 Online Resources and Forums

Online resources and forums provide accessible PDFs and detailed wiring diagrams for the 1982 Corvette; Websites like nrjvette․com and specialized Corvette forums offer free downloads‚ while platforms like Zip Corvette Parts sell official diagrams․ These resources often include interactive diagrams‚ color-coded charts‚ and troubleshooting guides․ Enthusiasts and restorers rely on these forums for community support and shared knowledge‚ ensuring accurate repairs and upgrades․ Many forums also provide step-by-step instructions and tips for interpreting complex wiring systems․

2․3 Specialized Corvette Parts Suppliers

Specialized Corvette parts suppliers offer authentic and detailed wiring diagrams for the 1982 model․ Zip Corvette Parts provides comprehensive diagrams‚ ensuring accuracy for restorations․ These suppliers cater to enthusiasts‚ offering high-quality materials and expert support․ Their resources are invaluable for both novice and experienced restorers‚ ensuring electrical systems function flawlessly․ By sourcing diagrams from these suppliers‚ owners can maintain the integrity and performance of their classic vehicles․ This support is crucial for achieving professional-grade results in Corvette wiring projects․

Understanding the Wiring Diagram

The 1982 Corvette wiring diagram provides a clear visual guide to the vehicle’s electrical system‚ detailing wire colors‚ connections‚ and component locations for precise diagnostics and repairs․

3․1 Color Coding for Wires

The 1982 Corvette wiring diagram uses color coding to identify wires‚ ensuring clarity and ease of repair․ Standard colors like yellow‚ red‚ and green signify specific functions‚ such as power‚ ignition‚ or lighting․ This system helps technicians trace circuits and diagnose issues efficiently․ For example‚ yellow wires often represent battery feeds‚ while red wires are typically connected to ignition-controlled components․ By referencing the color chart provided in the diagram‚ enthusiasts can accurately identify and repair electrical systems‚ maintaining the Corvette’s original functionality and performance․ This method is crucial for precise and safe electrical work․

3․2 Key Components and Their Functions

The 1982 Corvette wiring diagram highlights essential components like the battery‚ alternator‚ ignition module‚ and fuse box․ These parts work together to power systems such as lighting‚ ignition‚ and accessories․ The battery supplies energy‚ while the alternator recharges it․ The ignition module controls spark distribution‚ and the fuse box protects circuits from overcurrent․ Understanding these components’ roles is vital for troubleshooting and maintaining the electrical system‚ ensuring the Corvette operates smoothly and efficiently․ This knowledge helps enthusiasts identify failures and perform repairs effectively․

3․3 How to Read the Diagram

Reading the 1982 Corvette wiring diagram requires a systematic approach․ Start by identifying color-coded wires‚ which indicate specific functions․ Symbols represent components like fuses‚ relays‚ and connectors․ Trace wires between components to understand connections․ Use a highlighter to mark paths for clarity․ Pay attention to grounding points and power sources․ The diagram also shows circuit relationships‚ helping diagnose issues․ For larger diagrams‚ print and assemble pages to view the entire system․ Practice interpreting the layout to master electrical troubleshooting and repairs effectively․ This skill is crucial for maintaining and restoring the Corvette’s electrical systems․

Electrical Systems in the 1982 Corvette

The 1982 Corvette features essential electrical systems‚ including the battery‚ charging‚ ignition‚ and lighting systems․ These systems are interconnected and rely on the wiring diagram for proper function and diagnosis․

4․1 Battery and Charging System

The battery and charging system in the 1982 Corvette are crucial for starting and powering electrical components․ The system includes the battery‚ alternator‚ and voltage regulator․ Proper wiring‚ as shown in the diagram‚ ensures efficient charging and distribution of power․ The battery provides the initial power‚ while the alternator recharges it during engine operation․ The voltage regulator maintains stable voltage to prevent overcharging․ The wiring diagram helps identify connections and troubleshoot issues like dead batteries or charging malfunctions․ Regular maintenance‚ like checking terminals and belts‚ is essential for reliability․

4․2 Ignition System

The ignition system in the 1982 Corvette is essential for engine operation‚ relying on the wiring diagram to ensure proper connections․ It includes the ignition coil‚ distributor‚ spark plug wires‚ and ignition module․ The diagram simplifies troubleshooting issues like no-start conditions or misfires by tracing wires and identifying faulty components․ Proper wiring ensures the ignition module signals the coil correctly‚ producing sparks at the correct time․ Regular maintenance‚ such as replacing spark plugs and wires‚ is crucial for optimal performance․ The wiring diagram is a valuable tool for diagnosing and repairing ignition-related problems efficiently․

4․3 Lighting Systems (Headlights‚ Turn Signals‚ Brake Lights)

The 1982 Corvette wiring diagram provides detailed guidance for the lighting systems‚ including headlights‚ turn signals‚ and brake lights․ These systems rely on color-coded wires to ensure proper connections․ The diagram helps trace circuits for troubleshooting issues like faulty lights or malfunctioning signals․ For example‚ turn signals and brake lights share wiring paths‚ making the diagram essential for identifying faults․ Regular inspection of connectors and bulbs is recommended to maintain functionality․ The wiring diagram is a crucial tool for restoring and maintaining the Corvette’s lighting systems effectively․

Wiring Harness Overview

The wiring harness for the 1982 Corvette is a complex network of color-coded wires and connectors‚ essential for powering all electrical systems‚ ensuring reliability and safety․

5․1 Main Harness Components

The main wiring harness of the 1982 Corvette serves as the backbone of its electrical system‚ connecting key components like the battery‚ alternator‚ and fuse box․ It includes color-coded wires‚ connectors‚ and relays‚ ensuring power distribution to systems such as ignition‚ lighting‚ and accessories․ The harness is designed to withstand the vehicle’s high-performance demands while maintaining reliability․ Proper identification of each wire and connector is crucial for repairs‚ making the wiring diagram an indispensable tool for tracing circuits and diagnosing issues effectively․

5․2 Routing and Installation Tips

Routing and installing the wiring harness in your 1982 Corvette requires careful planning to ensure optimal performance and longevity․ Begin by identifying the main power sources‚ such as the battery and alternator‚ and trace their connections using the wiring diagram․ Secure the harness with clips or brackets to protect it from heat and vibrations․ Connect wires to components methodically‚ ensuring all connectors are firmly attached and grounded where necessary․ Use a torque wrench for connections that require specific torque specifications․ Avoid routing wires near moving parts or areas prone to pinching․ Test each connection as you go to prevent future electrical issues; Consider consulting tutorials or forums for additional guidance to ensure a smooth installation process․

5․3 Common Issues and Repairs

Common issues with the 1982 Corvette wiring harness include corrosion‚ damaged insulation‚ and loose connections․ Corrosion often occurs at terminals‚ while insulation cracks expose wires to short circuits․ Over time‚ connections may loosen due to vibrations․ To repair‚ inspect the harness thoroughly‚ replacing any corroded or damaged sections․ Use a wiring diagram to trace and identify faulty wires․ Clean terminals with a wire brush and apply dielectric grease to prevent future corrosion․ For severe damage‚ consider replacing the entire harness with a high-quality‚ OEM-style replacement․ Always consult the wiring diagram for accurate repairs․

This section details wiring diagrams for the fuel pump‚ ECM‚ and accessory circuits‚ ensuring precise connections for optimal functionality in the 1982 Corvette․ The fuel pump wiring diagram for the 1982 Corvette provides a detailed layout of the electrical connections necessary for proper fuel pump operation․ It includes the fuel pump relay‚ wiring colors‚ and connections to the Electronic Control Module (ECM)․ This diagram is crucial for installing or troubleshooting the fuel pump system‚ ensuring accurate wiring to prevent malfunctions․ By referencing this diagram‚ enthusiasts can identify the correct circuits and connectors‚ making repairs more efficient․ It’s a vital resource for maintaining the vehicle’s performance and reliability․ The Electronic Control Module (ECM) diagrams for the 1982 Corvette provide a comprehensive view of the computerized engine control system․ These diagrams detail the wiring connections between the ECM and various sensors‚ such as the oxygen sensor‚ coolant temperature sensor‚ and throttle position sensor․ They also outline the power and ground circuits essential for ECM operation․ By referencing these diagrams‚ technicians can diagnose issues like faulty sensor connections or corrupted wiring‚ ensuring the engine runs efficiently․ This resource is indispensable for understanding and repairing the Corvette’s advanced electronic systems․ The 1982 Corvette wiring diagram details the circuits for accessories like the radio‚ wipers‚ and other convenience features․ These circuits are designed to power non-essential systems while maintaining proper electrical flow․ The radio circuit‚ for example‚ is connected to the ignition switch‚ ensuring it only operates when the car is on․ Wiper circuits include controls for speed settings and interval functions․ These diagrams also highlight fuses and relays protecting the systems․ By tracing these connections‚ enthusiasts can repair or upgrade accessories‚ ensuring smooth operation of the Corvette’s modern conveniences․ The 1982 Corvette wiring diagram helps identify faulty wires and connections‚ guiding repairs for common electrical issues like blown fuses or malfunctioning circuits․ Identifying faulty wires and connections in the 1982 Corvette requires a systematic approach․ Start by consulting the wiring diagram to trace each wire’s path and connections․ Look for signs of wear‚ corrosion‚ or damage․ Use a multimeter to test conductivity and voltage drops․ Check for loose or corroded terminals‚ as these are common failure points․ Refer to the color coding in the diagram to ensure wires are correctly routed and connected․ Highlighting the diagram with markers can help track complex circuits․ Regular inspection and testing can prevent minor issues from becoming major problems․ Always ensure the ignition is off before probing wires to avoid electrical shocks․ The C3 Corvette often experiences electrical issues due to aging components and corrosion․ Common problems include faulty ECMs‚ corroded wiring connectors‚ and worn-out circuitry․ Blown fuses‚ malfunctioning gauges‚ and intermittent lighting are frequent complaints․ The wiring harness‚ especially in high-heat areas‚ can degrade over time․ Corrosion at connections‚ such as the battery terminals and ground wires‚ is another prevalent issue․ Consulting the wiring diagram helps pinpoint these problems by tracing circuits and identifying potential failure points․ Regular maintenance and inspections can prevent many of these issues from escalating․ Diagnosing electrical issues in the C3 Corvette requires a systematic approach․ Essential tools include a multimeter for voltage and resistance testing‚ a wiring diagram for circuit tracing‚ and a circuit tester for identifying live wires․ Techniques involve checking fuses‚ inspecting connectors for corrosion‚ and testing individual components like relays and sensors․ Using the wiring diagram‚ trace circuits to locate faults․ Isolating the problem by testing each component ensures accurate repair․ Always disconnect the battery before starting work to avoid electrical shocks or short circuits․ Safety and precision are crucial for effective diagnosis․ This section provides a comprehensive guide for replacing corroded wires‚ upgrading to modern components‚ and ensuring safety while performing electrical repairs on the 1982 Corvette․ Replacing corroded or damaged wires in the 1982 Corvette requires careful attention to the wiring diagram to ensure proper connections․ Start by identifying the faulty wires using the color-coded chart․ Use high-quality replacement wire that matches the original gauge and insulation․ Strip the damaged ends‚ and solder or crimp new connectors securely․ Apply heat-shrink tubing for protection․ Route the new wires precisely as shown in the diagram‚ avoiding pinch points․ Test the circuit to confirm functionality before reassembling components․ Always disconnect the battery to prevent electrical shocks during repairs․ Upgrading to modern electrical components can enhance the reliability and performance of your 1982 Corvette’s wiring system․ Consider replacing outdated fuses with a modern fuse box or installing a high-capacity alternator for improved charging․ LED lighting offers energy efficiency and longer lifespan․ Use the wiring diagram to identify compatible upgrades and ensure proper connections․ Always follow manufacturer instructions and safety guidelines when installing new components․ Avoid mixing old and new systems without proper testing to prevent electrical conflicts․ Consult forums or specialists for advice tailored to the C3 Corvette’s unique electrical setup․ When working on your 1982 Corvette’s wiring‚ always disconnect the battery to prevent electrical shocks or short circuits․ Use insulated tools to avoid accidental contact with live wires․ Ensure good ventilation‚ as soldering or wire stripping may release harmful fumes․ Keep a fire extinguisher nearby and avoid wearing loose clothing that could get caught in tools․ Consult the wiring diagram to understand the system before making changes․ Test each connection carefully after repairs to ensure safety and proper function․ Always follow proper grounding procedures to prevent damage to components or injury․ Wear protective gear like gloves and goggles․ Digital wiring diagrams for the 1982 Corvette provide enhanced clarity and accessibility‚ allowing users to zoom‚ search‚ and interact with specific circuits and components efficiently․ Digital wiring diagrams offer enhanced clarity and accessibility‚ allowing users to zoom in on specific circuits‚ search for components‚ and access detailed information quickly․ They reduce clutter and improve readability compared to physical diagrams․ Additionally‚ digital versions are easily shareable and can be updated with the latest corrections or modifications․ This makes troubleshooting and repairs more efficient‚ especially for complex systems like the 1982 Corvette’s electrical setup․ The convenience of digital formats ensures that enthusiasts and technicians can work more effectively․ Various software and apps are available for viewing wiring diagrams‚ such as Adobe Acrobat Reader‚ Foxit Reader‚ and SumatraPDF․ These tools allow users to zoom in‚ search for components‚ and navigate complex diagrams effortlessly․ Some apps also offer interactive features‚ enabling users to highlight or annotate specific sections․ For mobile users‚ apps like PDF Viewer and Docs Zone provide on-the-go access․ These tools enhance the efficiency of working with digital diagrams‚ making it easier to diagnose and repair electrical systems like those in the 1982 Corvette․ Printable PDF versions of the 1982 Corvette wiring diagram provide high-quality‚ detailed visuals for easy reference․ These files can be downloaded from sources like Zip Corvette Parts‚ specialized forums‚ and websites such as nrjvette․com․ Once printed‚ they offer a large-format view of the wiring layout‚ making it easier to trace connections and plan repairs․ PDFs are ideal for workshops or garages‚ allowing users to annotate and mark important sections․ This format ensures clarity and convenience‚ making it a valuable resource for restorers and technicians working on the C3 Corvette․ The 1982 Corvette wiring diagram is a crucial resource for restoration and repair‚ offering detailed insights into electrical systems‚ components‚ and troubleshooting‚ ensuring successful project completion․ The 1982 Corvette wiring diagram is a vital tool for restoration and repair‚ providing detailed insights into electrical systems and components․ It highlights the importance of understanding color-coded wires‚ key components‚ and troubleshooting methods․ Sources like official GM diagrams‚ online forums‚ and specialized suppliers offer reliable access to these resources․ By following the diagram‚ enthusiasts can identify faulty connections‚ address common issues‚ and perform DIY repairs effectively․ This guide ensures a smooth restoration process‚ helping to maintain the classic C3 Corvette’s functionality and aesthetic appeal․ Always start by thoroughly understanding the diagram’s color coding and symbols to avoid confusion․ Use digital versions for zooming capabilities and clarity․ Highlight key wires to trace connections easily․ Test wires before making repairs to ensure accuracy․ Work methodically to prevent missing critical connections․ Invest in quality tools for safe and precise work․ Regularly refer back to the diagram to verify repairs․ For complex issues‚ consult forums or seek professional advice․ Patience and attention to detail are key to successful wiring repairs․

Specific Wiring Diagrams for Key Features

6․1 Fuel Pump Wiring

6․2 Electronic Control Module (ECM) Diagrams

6․3 Accessory Circuits (Radio‚ Wipers‚ etc․)

Troubleshooting with the Wiring Diagram

7․1 Identifying Faulty Wires and Connections

7․2 Common Electrical Issues in the C3 Corvette

7․3 Tools and Techniques for Diagnosis

DIY Wiring Repairs and Upgrades

8․1 Replacing Corroded or Damaged Wires

8․2 Upgrading to Modern Electrical Components

8․3 Safety Precautions During Repairs

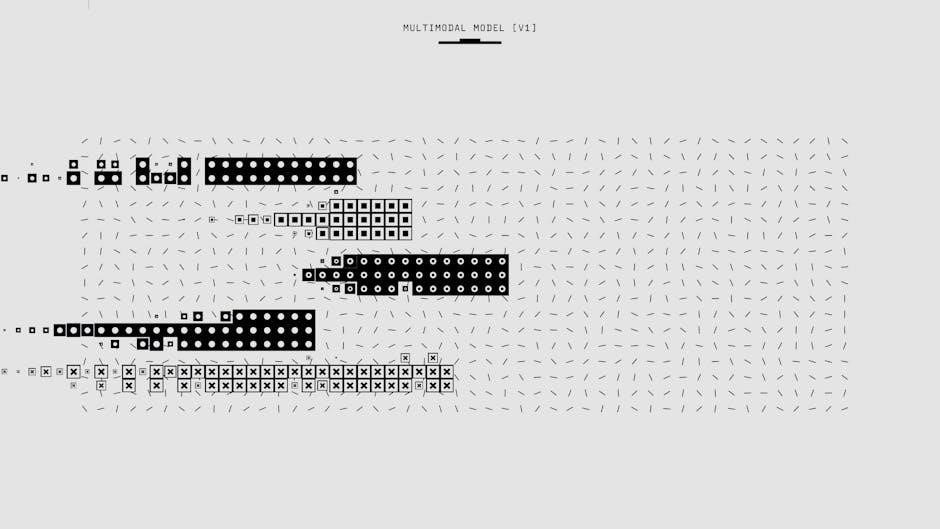

Interactive and Digital Wiring Diagrams

9․1 Benefits of Digital Diagrams

9․2 Software and Apps for Viewing Diagrams

9․3 Printable PDF Versions

10․1 Recap of Key Points

10․2 Final Tips for Working with Wiring Diagrams