ecowater systems water softener manual

Ecowater Systems Water Softener Manual: A Comprehensive Guide

HSBC UK provides tailored products and services for intermediaries‚ alongside dedicated support and resources‚ including affordability calculators and a broker login portal;

Understanding Your Ecowater System

HSBC UK caters specifically to FCA authorised mortgage intermediaries‚ offering a platform for accessing policy details and criteria through a dedicated website and chat support. This resource is designed to assist brokers‚ administrators‚ and deputies in navigating HSBC’s lending policies.

The system groups lending criteria into key categories for easy browsing‚ and provides an affordability calculator to estimate potential loan amounts for customers. HSBC emphasizes a professional and personal service‚ particularly for loans exceeding £1 million‚ assigning dedicated Relationship Managers.

Recent changes include the renaming of HSBC Life (UK) Ltd to Chesnara Life (UK) Ltd‚ with notifications sent to advisors and policyholders in December 2025/January 2026. Contact information for HSBC Asset Management UK is readily available for financial intermediaries seeking further assistance.

Components of the System

HSBC’s intermediary support extends to customized products and services‚ acknowledging the unique needs of their broker network. The platform facilitates access to residential lending criteria‚ categorized for efficient navigation‚ and offers a search function for direct access to specific details.

HSBC’s long-standing experience – over 160 years – fuels their commitment to opening opportunities for clients. They prioritize a dedicated approach‚ particularly for high-value loans‚ ensuring personalized relationship management. The recent rebranding of HSBC Life (UK) Ltd to Chesnara Life (UK) Ltd reflects ongoing adjustments.

Access to HSBC’s resources is streamlined through a broker login‚ and support is available via chat for frequently asked questions and case-specific queries routed to UK agents. This comprehensive system aims to empower intermediaries.

Initial Setup and Installation

HSBC UK focuses on providing a professional and personal service‚ particularly for loans exceeding £1 million‚ emphasizing a dedicated Relationship Manager for each intermediary. This approach mirrors the careful setup required for optimal performance. The platform’s lending criteria are meticulously grouped into key categories‚ simplifying the process for brokers.

Similar to a well-planned installation‚ HSBC’s support structure ensures intermediaries have the tools they need. Affordability calculators offer quick indications of lending potential‚ while detailed residential lending criteria provide comprehensive guidance. Access is restricted to FCA-authorised mortgage intermediaries‚ ensuring compliance.

The system’s responsiveness‚ via chat and dedicated agents‚ parallels the importance of a correctly installed and functioning water softener‚ ready to deliver optimal results.

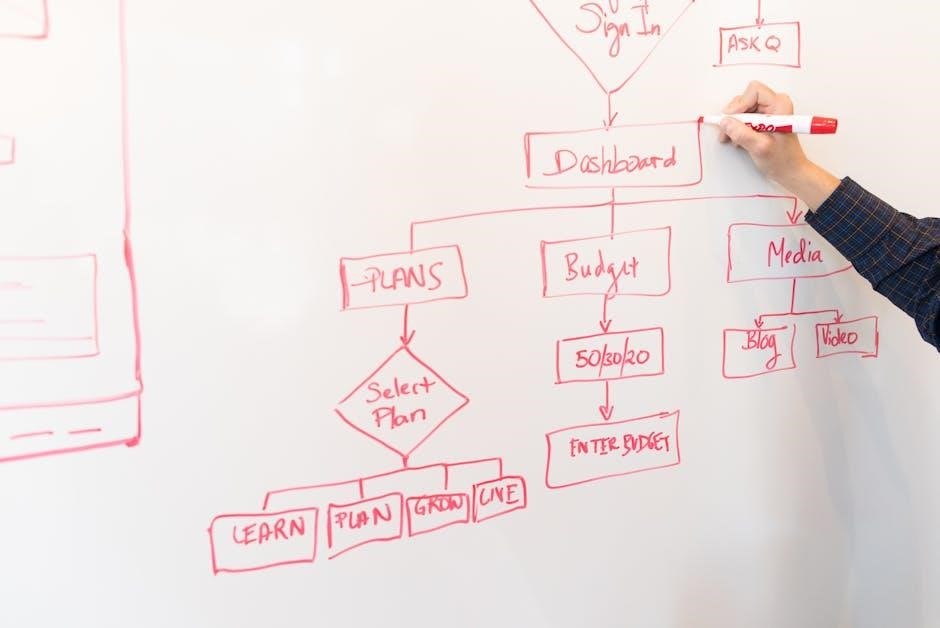

Programming the Control Valve

HSBC UK’s criteria navigation‚ allowing browsing by category or direct search‚ reflects the precise control needed when programming a water softener’s control valve. Just as a valve dictates regeneration cycles‚ HSBC’s policies dictate lending parameters.

The platform’s emphasis on clear information‚ akin to a user-friendly interface‚ ensures intermediaries can quickly locate relevant details. This mirrors the need for intuitive valve programming to optimize softening performance. Dedicated support‚ routing queries to UK agents‚ parallels troubleshooting valve settings for peak efficiency.

HSBC’s commitment to customization‚ offering tailored products‚ is similar to adjusting valve settings to match specific water hardness levels and household needs‚ ensuring optimal results for every customer.

Understanding the Regeneration Cycle

HSBC UK’s dedication to a “step-by-step guide” echoes the methodical nature of a water softener’s regeneration cycle. Like understanding lending criteria‚ grasping each phase – backwash‚ brine draw‚ rinse‚ and refill – is crucial for optimal performance.

The platform’s focus on providing answers to frequently asked questions mirrors the common inquiries about regeneration frequency and salt usage. Just as HSBC offers dedicated Relationship Managers‚ understanding the cycle ensures consistent water softening.

HSBC’s emphasis on opening up opportunities aligns with the softener’s role in providing clean water. The cycle’s efficiency‚ like HSBC’s tailored services‚ delivers value. Recognizing the cycle’s importance is akin to appreciating HSBC’s 160 years of experience.

Salt Usage and Types

HSBC’s customized products for intermediaries parallel the need to select the right salt for your Ecowater system. Just as HSBC caters to diverse financial needs‚ water softeners benefit from different salt options – solar‚ rock‚ or evaporated.

The platform’s emphasis on providing clear information‚ like HSBC’s lending criteria‚ highlights the importance of understanding salt purity and its impact on efficiency. Choosing the correct type‚ similar to selecting the right mortgage product‚ optimizes performance.

HSBC’s dedication to a professional service mirrors the careful consideration required for salt dosage and refill frequency. Proper salt usage‚ like responsible lending‚ ensures long-term benefits and avoids potential issues.

Troubleshooting Common Issues

HSBC’s support for intermediaries‚ including routing queries to UK agents‚ reflects the need for readily available solutions to common problems. Like addressing mortgage application hurdles‚ Ecowater systems can encounter issues requiring prompt attention.

Similar to HSBC’s FAQ chat function‚ a systematic approach to troubleshooting is crucial. Common concerns include no water softening‚ mirroring a declined loan application‚ or water leaks‚ akin to unexpected financial outflows. Control valve errors‚ like incorrect criteria application‚ also require investigation.

Just as HSBC provides dedicated Relationship Managers‚ understanding the system’s indicators and consulting the manual are vital. Proactive problem-solving‚ like careful lending practices‚ prevents escalation and ensures continued optimal performance.

No Water Softening

Similar to a mortgage application facing unexpected hurdles‚ a sudden lack of water softening can indicate several issues. Just as HSBC’s criteria require careful review‚ begin by verifying the system isn’t in bypass mode – essentially‚ the loan isn’t actively processing.

Check salt levels; insufficient salt mirrors inadequate funds for a transaction. Ensure the brine tank isn’t clogged‚ akin to blocked communication channels. A malfunctioning control valve‚ like an incorrect policy application‚ could also be the culprit.

If problems persist‚ consider resin bed exhaustion‚ similar to a saturated lending market. Contacting Ecowater support‚ mirroring HSBC’s agent assistance‚ is recommended for complex diagnostics and potential repairs.

Water Leaks

Much like identifying discrepancies in a mortgage application‚ promptly address any water leaks from your Ecowater system. Begin by inspecting all connections – fittings‚ valves‚ and the brine tank – mirroring a thorough review of HSBC’s lending criteria.

Tighten any loose connections‚ similar to correcting errors in a loan document. Check the drain line for obstructions‚ analogous to clearing communication channels with HSBC’s agents. A cracked tank or valve requires immediate attention‚ like addressing a critical policy issue.

If the leak persists‚ or you’re unsure of the source‚ contact Ecowater support for assistance‚ mirroring the support offered by HSBC’s dedicated Relationship Managers.

Control Valve Errors

Similar to encountering errors within HSBC’s mortgage criteria database‚ control valve errors require systematic troubleshooting. Begin by checking the power supply‚ ensuring it’s securely connected – akin to verifying a broker’s FCA authorisation.

Consult the control valve’s display for specific error codes‚ much like using HSBC’s search function to pinpoint relevant lending information. Refer to the manual for code definitions and suggested solutions. Resetting the valve may resolve minor glitches‚ comparable to refreshing a webpage.

If errors persist‚ contact Ecowater support‚ mirroring the process of escalating complex cases to HSBC’s UK agents. Do not attempt repairs beyond your expertise‚ as this could void the warranty.

Maintaining Your Ecowater System

Regular maintenance‚ much like HSBC’s dedication to a professional service‚ ensures optimal performance and longevity. Consistent upkeep prevents issues‚ mirroring how proactive monitoring avoids lending criteria complications.

Periodically inspect all connections for leaks‚ similar to verifying the accuracy of information within HSBC’s residential lending criteria. Address any leaks immediately to prevent water damage and inefficiency. Keep the area around the system clean and free of obstructions‚ ensuring easy access for servicing.

Follow the recommended schedule for cleaning the brine tank and inspecting the resin bed‚ analogous to HSBC’s regular updates to its policy and criteria. This proactive approach safeguards your investment.

Cleaning the Brine Tank

Similar to HSBC’s commitment to clear communication via their chat support‚ maintaining a clean brine tank is crucial for efficient operation. Sediment and salt buildup can hinder the regeneration process‚ reducing softening effectiveness‚ much like outdated criteria impacting lending decisions.

Periodically – typically every year or two – drain the brine tank completely. Remove any accumulated sediment with a gentle brush or vacuum. Avoid using harsh chemicals or abrasive cleaners‚ as these can damage the tank or affect water quality. Rinse thoroughly with clean water before refilling with salt.

Inspect the brine well for obstructions and ensure proper water flow. A clean brine tank ensures optimal salt dissolution‚ mirroring HSBC’s streamlined processes for intermediaries.

Inspecting the Resin Bed

Just as HSBC provides dedicated Relationship Managers for commercial brokers‚ the resin bed requires periodic attention. This is the heart of your water softening system‚ responsible for ion exchange – removing hardness minerals. Over time‚ resin beads can become fouled or coated with iron‚ sediment‚ or other contaminants‚ reducing their efficiency.

While a full resin bed replacement isn’t typically needed frequently‚ periodic inspection is vital. Look for signs of discoloration or clumping. A healthy resin bed should appear uniform in color and texture. If issues are detected‚ a professional resin cleaning may be necessary‚ similar to HSBC updating their lending criteria.

Regular monitoring ensures continued optimal performance‚ mirroring HSBC’s commitment to providing customized services.

Filter Replacement

Similar to HSBC’s regular updates to their policy and criteria‚ filter replacement is a crucial maintenance task for your Ecowater system. Pre-filters and post-filters remove sediment‚ chlorine‚ and other contaminants‚ protecting the resin bed and ensuring optimal water quality. Neglecting filter changes can lead to reduced water flow and decreased softening efficiency.

The frequency of filter replacement depends on your water quality and usage. Generally‚ pre-filters should be checked monthly and replaced every 3-6 months‚ while post-filters may last longer. Always refer to your system’s specific manual for recommended intervals‚ much like consulting HSBC’s Residential Lending Criteria.

Proper filter replacement safeguards your investment and maintains consistently soft water‚ mirroring HSBC’s dedication to client opportunity.

Regeneration Frequency Adjustment

Just as HSBC UK tailors products for intermediaries‚ your Ecowater system’s regeneration frequency can be adjusted to optimize performance and salt usage. The default settings are often conservative‚ and fine-tuning can lead to significant savings. Factors influencing regeneration frequency include water hardness‚ water usage‚ and resin bed capacity.

To adjust the frequency‚ access the control valve programming menu. You’ll typically find options to modify the regeneration time and the number of days between cycles. Monitor your water hardness regularly using a test kit – similar to how HSBC provides affordability calculators – to determine the optimal settings.

Decreasing regeneration frequency reduces salt consumption and water waste‚ promoting efficiency and cost-effectiveness‚ aligning with HSBC’s commitment to client benefit.

Bypass Valve Operation

Similar to how HSBC UK offers dedicated Relationship Managers for commercial brokers‚ your Ecowater system features a bypass valve for uninterrupted water supply during maintenance or emergencies. This valve allows you to isolate the softener without shutting off water to your entire home.

The bypass valve typically consists of three positions: ‘Service’ (normal operation)‚ ‘Bypass’ (water flows directly through‚ bypassing the softener)‚ and sometimes a ‘Slow Rinse’ position. Before performing any maintenance‚ such as filter replacement or resin bed inspection‚ always switch the valve to ‘Bypass’ to prevent water damage.

Ensure the valve is fully engaged in the desired position. Regular inspection of the bypass valve is recommended‚ much like HSBC’s criteria reviews‚ to ensure smooth operation and prevent leaks.

Water Hardness Testing

Just as HSBC UK provides affordability calculators for intermediaries‚ understanding your water hardness is crucial for optimal softener performance. Regular testing determines the level of minerals – calcium and magnesium – in your water supply. This dictates the necessary regeneration frequency and salt dosage for effective softening.

You can use readily available water hardness test kits‚ often found at hardware stores‚ or send a sample to a professional laboratory. Test kits typically provide results in grains per gallon (GPG) or parts per million (PPM). Knowing your baseline hardness allows you to accurately program your Ecowater control valve‚ mirroring HSBC’s customized product offerings.

Retest periodically‚ especially if you notice changes in water quality‚ to maintain efficient operation and protect your plumbing‚ similar to HSBC’s ongoing criteria updates.

Ecowater Warranty Information

Similar to HSBC UK’s commitment to its intermediaries‚ Ecowater stands behind its systems with a comprehensive warranty. The specific terms and duration vary depending on the model and components. Generally‚ the control valve is covered for a longer period than the tank or other parts‚ mirroring HSBC’s tiered product offerings.

The warranty typically covers defects in materials and workmanship under normal use. It’s essential to register your system promptly after installation to activate the warranty. Keep your proof of purchase and warranty documentation in a safe place.

Review the warranty details carefully to understand what is covered and any limitations. Like HSBC’s policy criteria‚ certain conditions may void the warranty‚ such as improper installation or maintenance. Contact Ecowater support for specific warranty claims.

Contacting Ecowater Support

Ecowater‚ much like HSBC UK’s dedicated broker support team‚ offers multiple avenues for assistance. For immediate answers to frequently asked questions‚ explore their online resources and FAQs – akin to HSBC’s Chat feature. If you require more personalized help‚ a direct phone call to their customer support line is recommended.

Their website provides contact information‚ including phone numbers and email addresses‚ categorized by department. For complex issues or warranty claims‚ detailed documentation may be required‚ similar to HSBC’s case-specific queries.

Consider utilizing online forums or communities dedicated to water softeners‚ where other users may have encountered and resolved similar problems. Ecowater aims to provide a professional and responsive service‚ mirroring HSBC’s commitment to its intermediaries;